Optimal robot operation for wire harness production

- Subject:Cyber-Physical Robotics

- Type:Mastersthesis

- Date:ASAP

- Supervisor:

- Links:Tender

-

During this thesis, the optimal on demand planing of robot action during batch size

one wire harness production is examined

MOTIVATION:

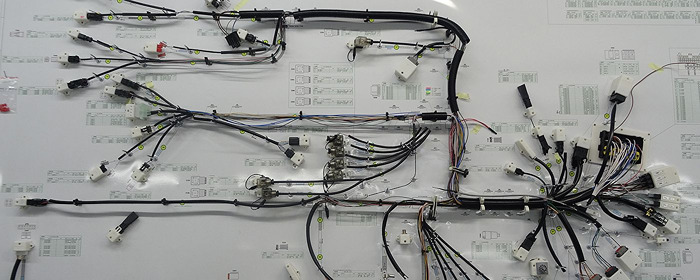

Wire harness production is predominantly a manual process, where each wire

is meticulously prepared by hand on assembly boards (Figure 1). Workers are

well-versed in every step of the process and can adapt flexibly to various situ-

ations. Their ability to perform highly dexterous movements, such as pushing

occluding wires aside while pinning another wire, is crucial.

However, when automating this process with robots, the inherent human exper-

tise is absent. Robotic movements are governed by predetermined algorithms,

making it challenging to handle unforeseen situations effectively. Additionally,

robots lack the dexterity of human operators, leading to additional constraints

during production, such as the order of pinning wires.

This underscores the need for developing a comprehensive wiring strategy to

bridge the gap between manual dexterity and robotic automation.

Cooperation partner:

Kromberg & Schubert is a globally leading specialist with 120 years company

history in wiring systems for the automotive industry. The company offers

significant prospects in a forward-looking industry. Kromberg & Schubert is

experienced and popular among working students and interns. They support

practical thesis projects with substantial input and commitment. The company

is open to subsequent employment if it suits both parties.

GOALS:

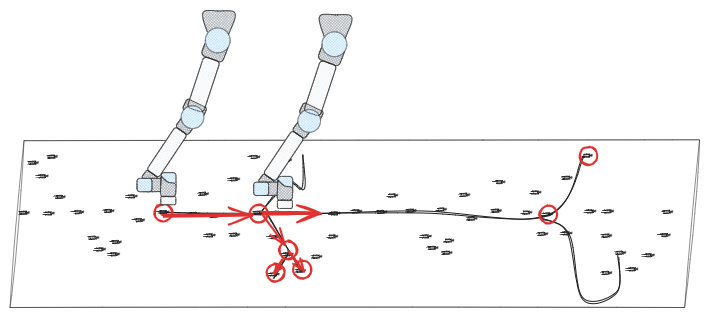

The aim of this thesis is to develop a rule-based method for structuring the

wire harness manufacturing process to optimize robot operation (Figure 3).

To achieve this, the manufacturing process will first be analyzed. Based on

discussions with members of Kromberg & Schubert, the necessary rules will be

established. Subsequently, the method will be tested through simulation. To

further the understanding of the current manufacturing processes, a visit of a

European production plant is possible.

HELPFUL PRIOR KNOWLEDGE:

- Robotics

- Optimization theory

- Interest in robotic manufacturing processes