Test rig design: salt + colour = electrolyte?

- Type:Masterarbeit

- Date:nach Absprache

- Supervisor:

- Links:Tender (german)

-

Performing and applying dimensional analysis of electrolyte baths.

Motivation

Electroplating is one of the most important processes for finishing workpieces with metallic layers.

Besides cosmetic finishing, it is mainly about functional finishing such as protection against corrosion, increasing the conductivity or adding catalytic properties.

In the field of contract electroplating, various layers are applied to a workpiece in a manual process.

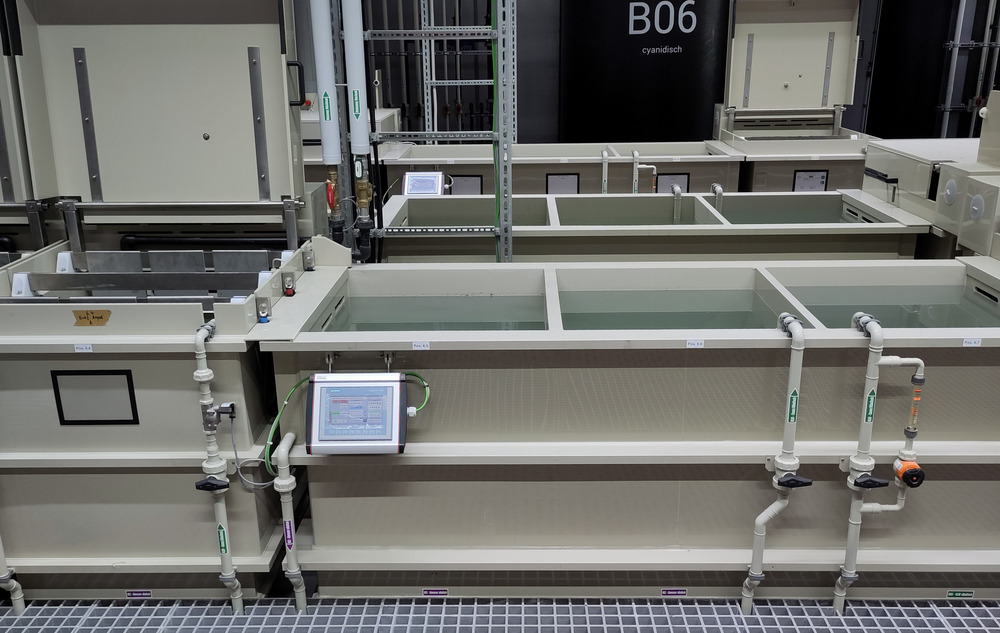

In an effort to automate parts of the process, an electroplating unit (see Figure 1) is being set up at the IRS.

In addition to numerical simulations, experiments will be carried out with this unit in order to test set-ups in the field before application.

A proxy electrolyte is used because galvanic electrolytes are too expensive in relevant quantities and are available in solutions with extreme pH values.

Using methods of dimensional analysis, a principle is to be developed with which, on the basis of test results carried out with the proxy electrolyte, the following can be determined

Objectives

A principle is to be developed with which the result space of an experiment on a galvanotech system can be estimated by carrying it out on a proxy electrolyte as an example.

For this purpose, it should first be researched which dimensions of an electrolyte change during the process.

For this, on the one hand the process and on the other hand the system with process basin and three rinses must be understood.

The second step is to show how the researched dimensions are reflected in a proxy electrolyte.

These correlations are to be validated by series of experiments and an error analysis is to be carried out.

Helpful prior knowledge

- Basics of measurement technology

- Interest in process and automation technology

- High interest in physical and chemical effects